- Overview

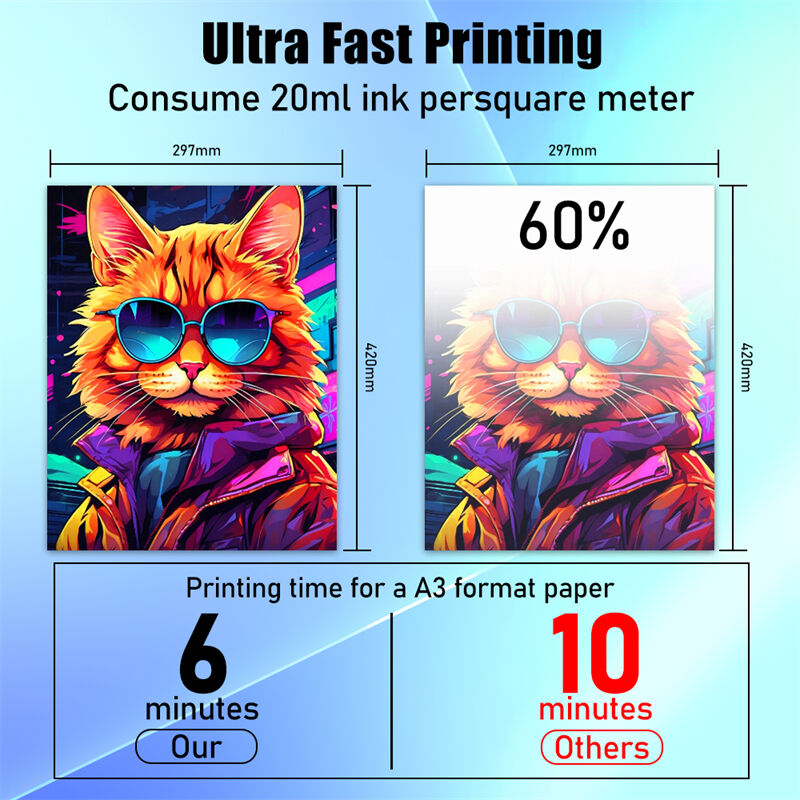

- Specifications

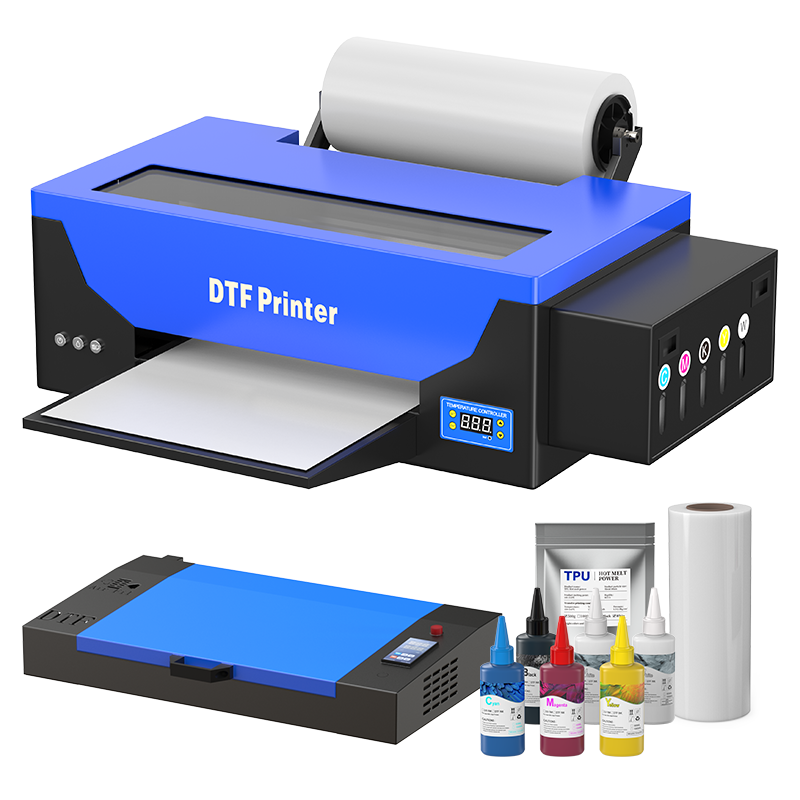

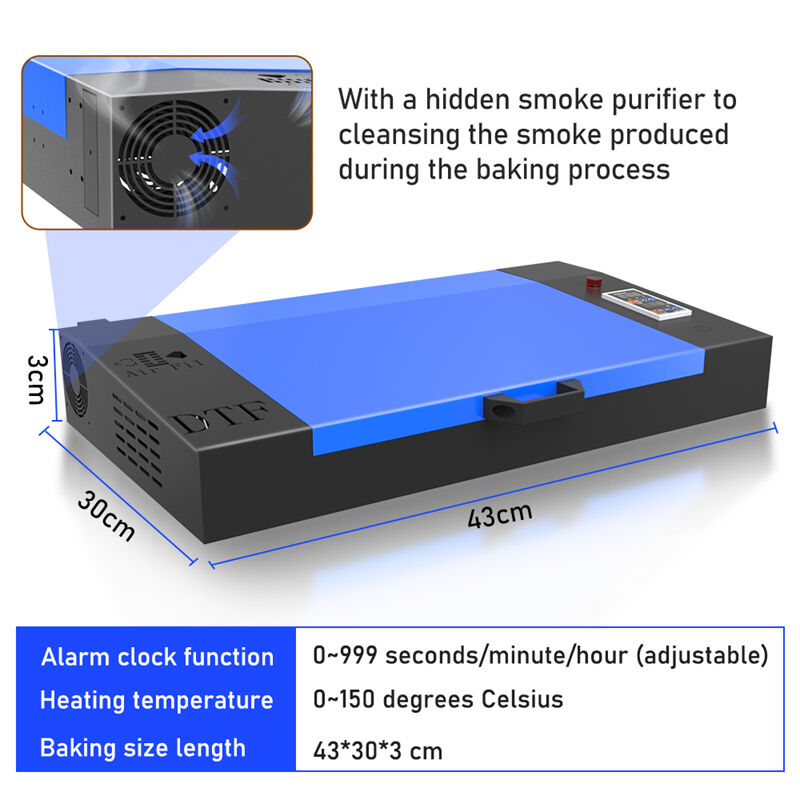

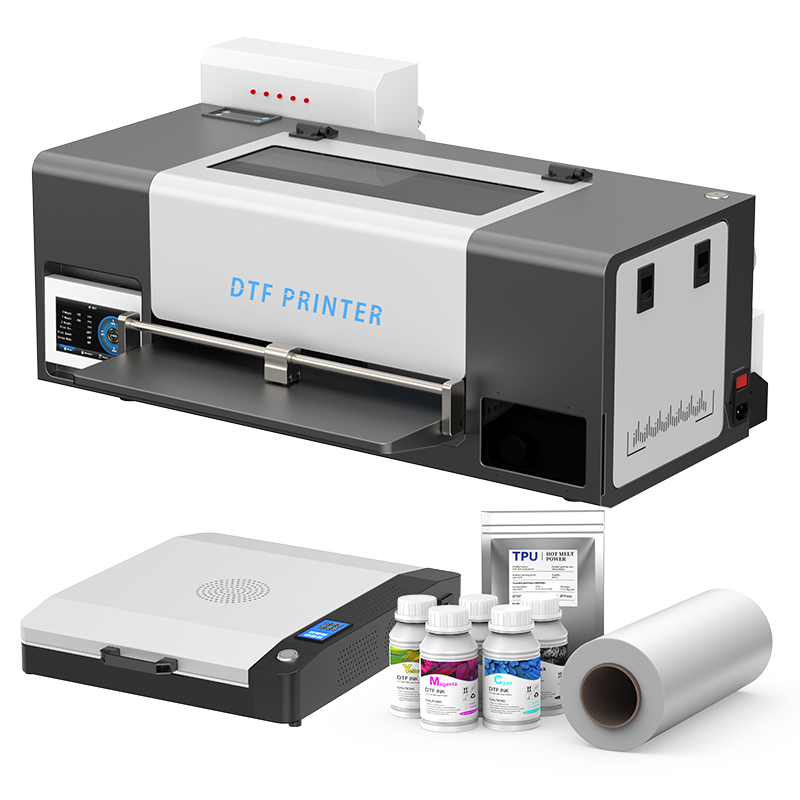

- Description

- Applications

- Competitive Advantage

- Recommended Products

Overview

| Place of Origin: | China |

| Brand Name: | COLORSUN |

| Model Number: | KSR1390 DTF Printer |

| Certification: | CE |

| White ink circulation system: | have |

| Nozzle: | For Epson R1390 |

| Printing size: | A3 |

| DPI: | 2880*1440DPI |

| Language: | Chinese/English |

| Software: | RIP10.1 |

| Applicable system: | Window 7/10/11 |

| Colors: | CMYK+W W |

| Ink consumption: | 1sq.m/20ml |

| Ink supply system: | 6colors CISS |

| White ink mixing: | Have |

| Minimum Order Quantity: | 1 |

| Price: | $1550 |

| Packaging Details: | Wooden box |

| Delivery Time: | 7~15 days |

| Payment Terms: | T/T, MoneyGram, Western Union, Credit Card, Cash, PayPal, Escrow |

| Supply Ability: | Own factory |

Specifications

| Quantity | MAO Zhong | Volume | Packaging size | Packaging |

| 1 | 49KG | 50KG | 86*41*48cm | Wooden box |

Description

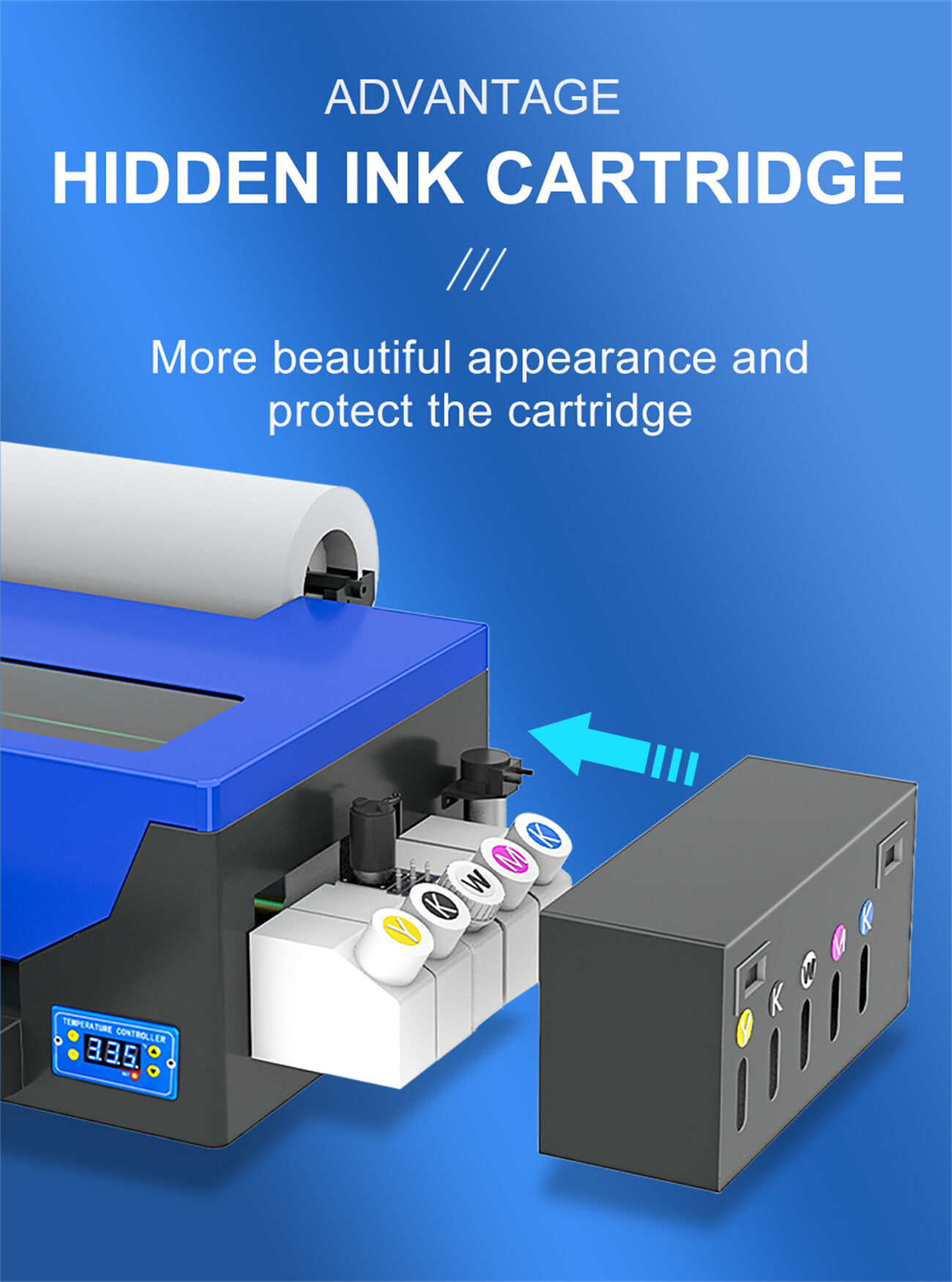

ADVANTAGE

PRODUCT FEATURE

The new r1390 printer is more user-friendly in design, in line with the user's operating habits, easy to use.

• LED light tube, not only beautiful,at night can also see the printer working state

• Automatic white ink mixing,so that the white ink does notprecipitate

• Temperature & humiditydisplay: convenient forcheck

• Heating after printing to solidifythe ink and prevent the ink fromflowing

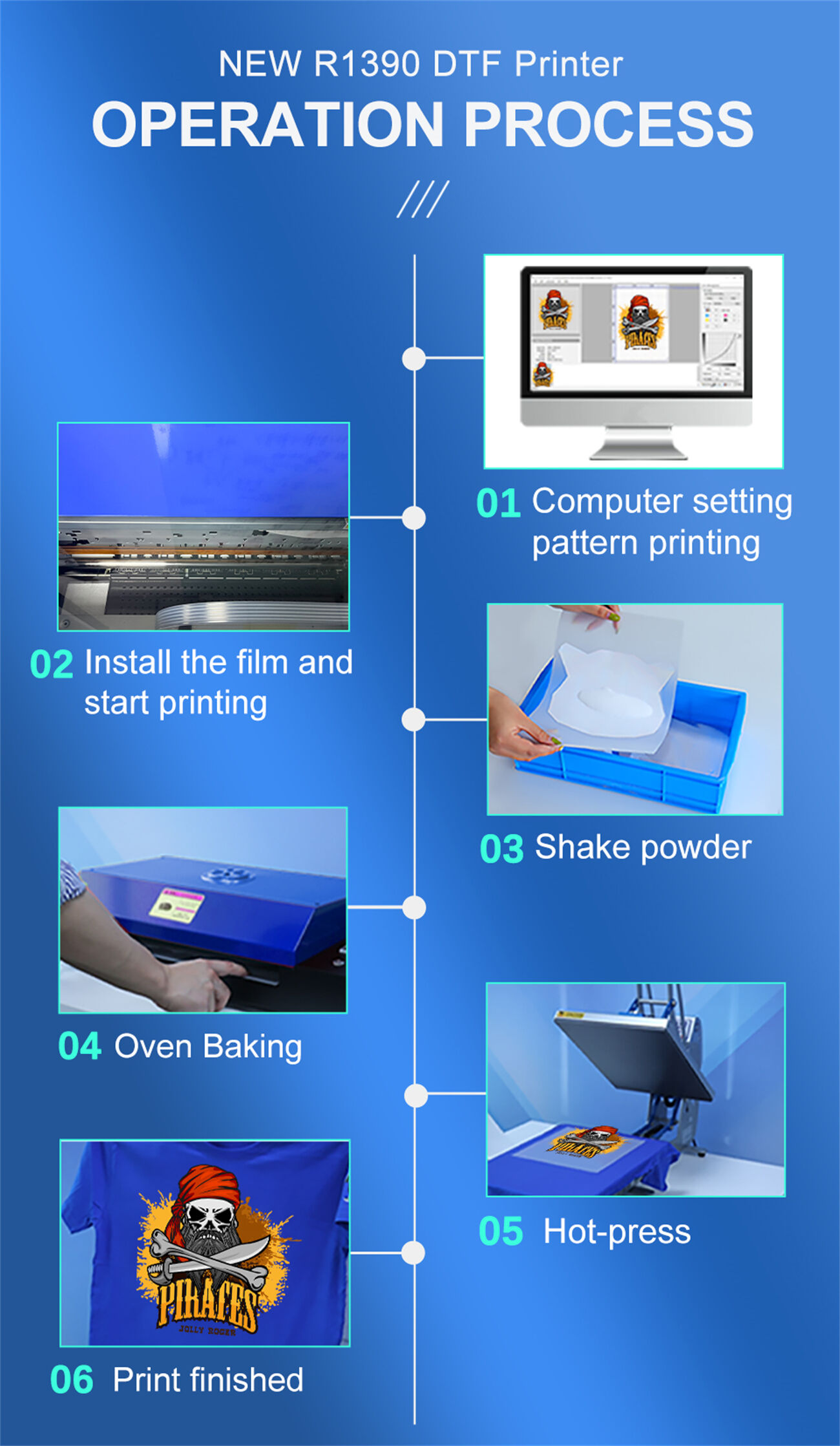

NEW R1390 DTF Printer

OPERATION PROCESS

01 Computer setting pattern printing

02 Install the film and start printing

03 Shake powder

04 Oven Baking

05 Hot-press

06 Print finished

Applications

1. Use software draw the pictures , and then use the printer to print the pattern on the PET machine

2. Sprinkle an appropriate amount of hot melt poweron the printed PET film and shake off the excess hot melt power

3. Put the PET film on the heat transfer machine and back for 5-7 minutes ,until the hot melt powder melts , take out the PET film

4. Lay the T shirt flat on the heat transfer amchine and stick the sidesprinkled with hot melt powder on the T shirt for pattern hot samping and the hot stamping takes 15-20 seconds

Competitive Advantage

1.Automatic white ink mixing,so that the white ink does notprecipitate

2.Pre heating after printing:make the ink solidify initially,it will not flow on the film

3.Temperature & humiditydisplay: convenient forcheck

4.White ink circulation system makes the ink smoother, continuous print And out ink

5.Supports sheet and roll printing